Low price Z purlin forming machine supplier, our purlin forming machine is the industry's best value in an automated purlin rollforming system. And we are also capable of manufacturing C, U, and Z shapes purlins. With great after-sale service, timely delivery, we are your best roll forming machine suppliers choice.

Material

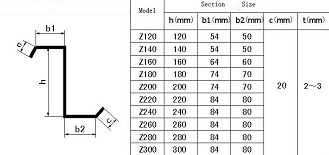

(1)Coil Width: According the size

(2)Suitable Coil Thickness: 2.0-3.0mm

(3)Suitable Raw Materials: Q235,Galvanized steel coil

Machine Components

(1) Manual Un-coiler 1 set

(2) Leveling Device 1 set

(3) Roll-Forming M/C 1 set

(4) Hydraulic Cutting(10 cutter) 1 set

(5) PLC Control System 1 set

(6) Product Rack (un-powered) 1 set

Technical Specification:

(1) Manual Un-coiler

|

Un-power; manual un-coiler, single head Spindle expansion: Φ480~Φ520mm Max load capacity: 3 tons It includes a simple brake device Outer coil deameter φ1200mm |

(2)Roll Forming Machine: 13 steps to form; Material of Roller: GCr15, Voltage: 380V/50Hz, Main line speed: 0- 10m/min

(3)Hydraulic Cutting

|

Stop to cut, Post cut and no waste the material Cutting tool material: Cr12, Include 5 pairs of shears. The lengh tolerance is ±2.0 mm

|

Hydraulic cutting machine has features: Stop to cut, Post cut and no waste the material, Cutting tool material: Cr12, Include 5 pairs of shears. The lengh tolerance is ±2.0 mm

(4) PLC Control System controls the quantity, which has the features of length automatically and LCD screen.

(5)Product Rack (Un-powered), Two piece total 6 meters.

OPTION DEVICE

|

(1) Hydraulic Un-coiler Hydraulic system to expand coil inner hole; inner coil diameter φ508mm, Outer coil deameterφ1200mm, Frequency Inverter to regulate turning speed; Automatic stop device; Load capacity = Max.3Tons; |

(2) Punching Device

Stop to punch, and post punch.

Punch two slotted hole in the end of formed panel, the distance of two holes

Changed according the C section size. Notice the punch can use from the C140.