Double layer roll forming machine which can separate produces corrugated roof and IBR roof in one line or similar two profiles. Using one frame, make two final products. Low cost and high working efficiency forming machine.

Technical Requirement

(1) Processing accuracy is according to relevant project requirement of main technical parameter;

(2) No abnormal vibration, production noise is under 85db when running;

(3) For hydraulic components and hydraulic station, ensure there's no leakage or natural damage under normal use and maintenance, also provide change or repair for users;

(4) Welding requirement: Appearance size of welded joint of all welding parts should be uniform, connection with base metal is smooth and steady; make the surface well-proportioned and beautiful by splash remove and necessary polish;

(5) To eliminate internal stress of all steel structure parts by annealing treatment after welding, make it with high strength and high accuracy stability;

(6) For surface finish machining of production line, it adopts anti-rust measures such as anti-rust oil coating during manufacturing, assembly and transportation, or corrosion prevention treatment as anti-rust paint coating for non-surface machining.

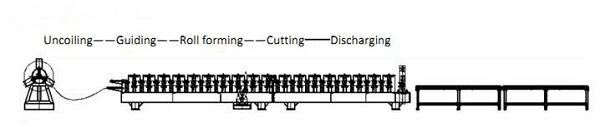

Flow chart

Other Components for Double Layer Roll Forming Machine

| NO. | NAME | Unit | Q'ty |

| 1 | Un-coiler | set | 1 |

| 2 | Guider | set | 1 |

| 3 | Double layer roll forming machine | set | 1 |

| 4 | Cutting machine | set | 1 |

| 5 | Un-powerd stacker | set | 1 |

| 6 | Hydraulic system | set | 1 |

| 7 | Electrical cabinet | set | 1 |